Shanxi Solid Industrial Co., Ltd., a leading Flanged Y-strainer manufacturer in China. Specializing in durable cast iron and ductile iron flange type Y-strainers for reliable filtration solutions.

TAGS: Ductile Iron Valve

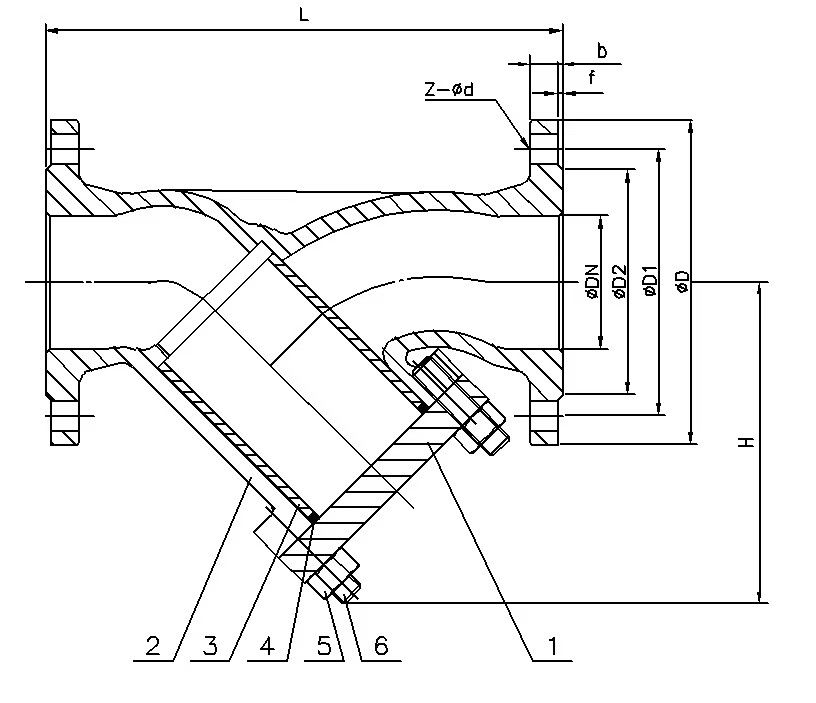

Y Strainer - Flanged Ends

Material: Ductile iron GGG40/50 /Cast Iron GG25/ Carbon Steel

Standard: BS2080, DIN3201-F1, MSS-SP

Flange drilling is according to BS4504, DIN2501, and ANSI B16.1 PN10, PN16

Working pressure: 10bar/16bar/25bar

Testing pressure:

Shell: 15bar/24bar/37.5bar

Seal: 11bar/17.6bar/27.5bar

Bonnet: Cast iron/Ductile iron

Screen: Stainless steel 304

Coating: Internal and external with fusion bonded epoxy coating min250μm or Liquid epoxy painting

Y-Type strainers available in Stainless Steel, Forged Steel, Cast Steel or Cast Iron. Available in threaded or flanged ends.

Y strainer (Y type strainer) used extensively to strain foreign matters from pipe lines and provide economical protection for costly pumps, meters, valves and other similar mechanical equipment.

The strainers carry out superficial sieving of the water, retaining those particles that are bigger than the screen holes. We have disposal strainers in "Y" shape.

Regarding their installation, the strainers can be either equipped with flanges fitted on their ends or with internal threads.

Standard: BS2080, DIN3201-F1, MSS-SP

Flange drilling is according to BS4504, DIN2501, and ANSI B16.1 PN10, PN16

Size Range: 50-600MM

Working pressure: 10bar/16bar/25bar

Testing pressure:

Shell: 15bar/24bar/37.5bar

Seal: 11bar/17.6bar/27.5bar

Material: Ductile iron GGG40/50 /Cast Iron GG25/ Carbon Steel

Bonnet: Cast iron/Ductile iron

Screen: Stainless steel 304

Coating: Internal and external with fusion bonded epoxy coating min250μm or Liquid epoxy painting

Features:

Material: Cast Iron

Graphite/316 Bonnet Gasket

Y type strainer

SS 304 screen

AS/NZ 4158 FBE coated body (Blue colour)

Stainless Cover Bolts

Flange: BS10 Table D/E

Product Dimensions:

ANSI CAST IRON Y STRAINER

ITEM | PARTS NAME | MATERIAL |

1 | BODY | CAST IRON(ASTM A126-B) |

2 | SCREEN | STAINLESS STEEL |

3 | GASKET | GRAPHITE |

4 | BONNET | CAST IRON(ASTM A126-B) |

5 | PLUG GASKET | GGG40 GRAPHITE |

6 | BOLT GASKET | CARBON STEEL |

DIMENSIONS(mm) | |||||||||

DN | L | D | D1 | D2 | b | Z-d | f | H | KG |

1/4" | 130 | 95 | 65 | 45 | 14 | 4-14 | 2 | 76 | 2.33 |

3/4" | 150 | 105 | 75 | 58 | 16 | 4-14 | 2 | 83 | 3 |

1" | 160 | 115 | 85 | 68 | 16 | 4-14 | 2 | 91 | 4 |

1 1/4" | 180 | 140 | 100 | 78 | 18 | 4-18 | 2 | 111 | 6 |

1 1/2" | 200 | 150 | 110 | 88 | 18 | 4-18 | 3 | 118 | 7 |

2" | 230 | 165 | 125 | 102 | 20 | 4-18 | 3 | 178 | 11.8 |

2 1/2" | 290 | 185 | 145 | 122 | 20 | 4-18 | 3 | 211 | 16.45 |

3" | 310 | 200 | 160 | 138 | 22 | 8-18 | 3 | 202 | 19 |

4" | 350 | 220 | 180 | 158 | 24 | 8-18 | 3 | 226 | 24.9 |

5" | 400 | 250 | 210 | 188 | 26 | 8-18 | 3 | 264 | 35.6 |

6" | 480 | 285 | 240 | 212 | 26 | 8-23 | 3 | 309 | 51.9 |

8" | 600 | 340 | 295 | 268 | 30 | 12-23 | 3 | 410 | 92.3 |

10" | 730 | 405 | 355 | 320 | 32 | 12-27 | 3 | 444 | 142 |

12" | 850 | 460 | 410 | 378 | 32 | 12-27 | 4 | 486 | 210 |

14" | 980 | 520 | 470 | 438 | 36 | 16-27 | 4 | 595 | 284.7 |

16" | 1100 | 580 | 525 | 490 | 38 | 16-30 | 4 | 673 | 399.4 |

1 | Body | Cast iron/Ductile iron |

2 | Bonnet | Cast iron/Ductile iron |

3 | Screen | Stainless steel |

Face to face is according to ANSI class 125/150 |

Flange drilled is according to ANSI B16.1/B16.5 |

1 | Working Pressure | 125PSI | 150PSI |

2 | Shell Pressure | 300PSI | |

3 | Seat Pressure | 200PSI | |

Size(DN) | 2’’ | 2-1/2’’ | 3’’ | 4’’ | 5’’ | 6’’ | 8’’ | 10’’2’ | 12’’ |

L | 225.4 | 273 | 292 | 352.4 | 420 | 470 | 543 | 660.4 | 762 |

H | 130 | 150 | 175 | 230 | 260 | 300 | 360 | 440 | 525 |

D | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 |

n-∅d | 4-∅19 | 4-∅19 | 4-∅19 | 8-∅19 | 8-∅22 | 8-∅22 | 8-∅22 | 12-∅25 | 12-∅25 |

K | 120.5 | 139.5 | 152.5 | 190.5 | 216 | 241.5 | 298.5 | 362 | 432 |

D | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 |

n-∅d | 4-∅19 | 4-∅19 | 4-∅19 | 8-∅19 | 8-∅22 | 8-∅22 | 8-∅22 | 12-∅25 | 12-∅25 |

K | 120.5 | 139.5 | 152.5 | 190.5 | 216 | 241.5 | 298.5 | 362 | 432 |

Ductile iron valves can be customized according to customer needs.

Customized ductile iron valves can be designed and manufactured according to specific dimensions, shapes, materials, and process requirements.

Customers can provide their own design drawings or requirement specifications, or communicate with suppliers to customize ductile iron valves that meet specific requirements. Customized ductile iron valves can meet the special needs of different engineering projects, improve the adaptability and reliability of the project.

Get In Touch

Please leave your request for any product you wish. We will be happy to search it for you in our databases or offer its custom synthesis.